At Ampro Electric we work as a team united to get the job done safely. Let’s work together.

Services

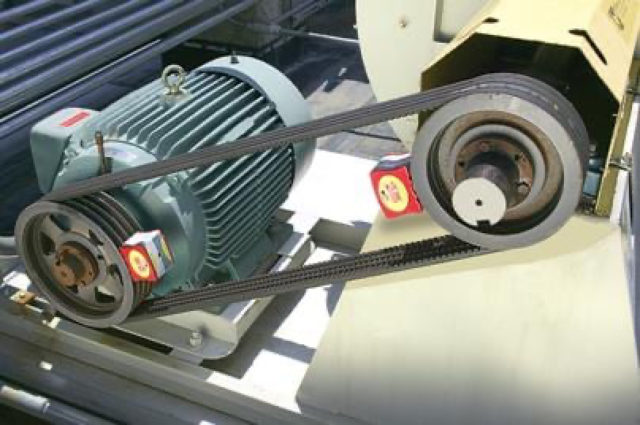

Electric Motor & Pump Repair Services

At Ampro we offer a wide variety of services that fall into two categories. Our In Shop Repair done at one of our many location or our field services where our team of experts will come to you.